|

Two different types of threading processes are used at Whitelaw Rigging.

Roll threading is a cold forming process where a blank having an outside diameter between the major and minor diameters of the finished thread is rolled between hardened steel dies. The dies penetrate the blank to form the thread roots, and displace material radially outward to form the crests.

Unlike cut threading, metal is neither removed nor wasted, but displaced.

The cold forming process strengthens the threads in three ways: tension,shear, and fatigue resistance.

The grain structure of the thread is not cut. Instead it is reformed in continuous unbroken lines following the thread contours. Rolled threads have increased resistance to stripping because of the improved grain flow.

Cut threading is a process where material is removed or cut away from a round bar. Cut threading is advantageous for short runs, large diameter bolts, and some special materials. Cut threading has a shorter set-up but longer threading time per bolt. Whitelaw Rigging Anchor Bolts offer roll thread bolts in 5/8”, 3/4”, 1” and 1-1/4" diameters. All standard diameters are available cut thread. Both cut and roll threaded bolts meet current ASTM standards for non-headed bolts.

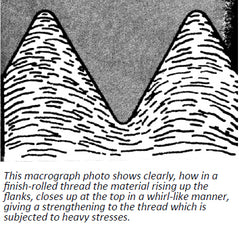

This macrograph photo shows clearly, how in a finish-rolled thread the material rising up the flanks, closes up at the top in a whirl-like manner, giving a strengthening to the thread which is subjected to heavy stresses.

Whether your requirement is for a truckload of bolts, or a box, Whitelaw Rigging has the proven technology and methods to respond quickly and accurately. Anchor bolts are a “quick turn-around” business. When you need performance, call Whitelaw Rigging.

|